Urban hybrid-electric vehicles for waste collection with ultra-capacitor system

Study, analysis and development of new technologies in hybrid electric motorization for the urban solid waste collection truck

Technical objectives

New product description

Main technological improvements

Specific technical objectives of the project.

The main technical objective to be developed by FCC is to design and develop an innovative new vehicle for municipal waste collection which does not exist in the market so far. The technical objectives pursued are:

- Substantial reduction of harmful emissions into the atmosphere when the vehicle is stopped at collecting phase and starts in urban areas (pure electric mode).

- Substantial decrease of harmful emission to atmosphere on transport mode (hybrid mode, natural gas combustion engine).

- Substantial decrease of noise pollution both in electric mode and hybrid mode (with natural gas engine).

- Energy savings compared to the equivalent diesel or natural gas vehicles

- Maintaining loading capacity from current vehicles increasing the maximum authorized mass of the proposed chassis.

- Development and adaptation to the of new technology and design ultracapacitors system, specifically fitted for this application, that allows operation as a "hybrid series" in displacement and "pure electric" (with stand heat engine) in compaction and starts on urban route with power and energy enough to cover the entire route of wastes collection under the conditions above.

Innovative new vehicle

for municipal waste collection

New product description.

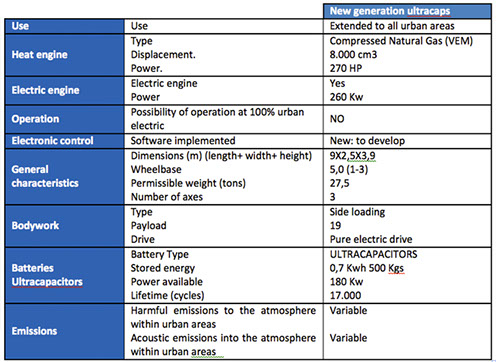

To fulfill the main target, innovative technology is developed with two operating modes: electric-hybrid and pure electric, in which ultracapacitors are used instead of batteries.

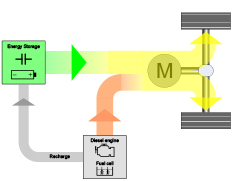

The Series Hybrid Electric drive system proposed disengages the combustion engine from the wheels, and the drive train is actuated by an electric engine. The Hybrid Series System has different energy sources:

- Energy storage system is represented through Ultracapacitors System, recharged with the proposed electronic system, and specific to these particular application.

- Chassis’ thermal engine.

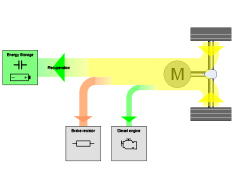

- During deceleration the electric engine can work as a generator and also be a source of energy.

The flows of energy from and towards these energy sources will be managed through a system of own management to be developed.

A small part of regenerative energy is used to move the internal combustion engine so the fuel injection stops (comparable with the "engine braking" of a car downhill).

The result is thus a reduction of the vehicle emissions - and this energy flow is considered "green" -.

Energy flow during the collection

In this phase, the internal combustion engine of natural gas is completely stopped and the whole energy required to drive the hydraulic pumps which drive the body are provided by the ultracapacitors to an intermediate auxiliary electric engine.

For this, we should implement a method for the start-stop of the whole set in the electric-electronic vehicle’s management system.

The start-stop function must slow down combustion engine to stop it in case of a vehicle stop and then start it automatically when the vehicle has overcome inertia.

The use of ultracapacitors instead of batteries is done to get a vehicle that allows carrying extra load and therefore this vehicle should became more profitable. With this solution the pursued objectives of reducing pollutant emissions and getting energy savings will be achieved in a profitably way. It is obtained by both a competitive technology on the market, in line with current environmental objectives.

The use of Ultracapacitors on such vehicles supposes reducing energy storage capacity, but, on the other hand the power supply is increased considerably, which makes the process cheaper (and hence applicable to the market).

With the new vehicle is intended to achieve 20-30% energy savings in terms of kwh of energy consumed, which is between 240 and 360 kwh in the case of compressed natural gas vehicle.

In the starting phase, power is provided to the electric traction engine, to the drive shaft, and finally to the wheels of the vehicle by the ultracapacitors system.

Once the inertia of the equipment is reached, the energy is provided by the combustion engine, which runs on compressed natural gas.

The energy supplied by a system of energy storage as the ultracapacitors system can be considered "green" energy because it can be regenerated by the kinetic energy of the vehicle during the braking.

Vehicle’s performance with ultracapacitors

During vehicle deceleration, the drive shaft deliveries energy to the system so that in the best case all the regenerative power is absorbed by a storage system of ultracapacitors.

Energy flow diagram of a series hybrid system during acceleration

Energy flow diagram of a series hybrid system during deceleration

The environmental advantage is that the vehicle sometimes uses electrical drive (more efficient), and as a consequent of that there are lower fuel consumption and lower emissions.

This advantage is even greater in urban environments, where the average speed of the route is low and includes a large number of starts and stops.

The new vehicle incorporates the start-stop function, which lets stop the heat engine and use electricity as single source of energy at low speeds or when the vehicle is stationary.

Technological improvements.

Developing this vehicle represents the achievement of a number of advantages:

- Energy savings compared to diesel or natural gas equivalent vehicles. Therefore the pollutant emission is clearly smaller.

- Increased power output (180 kW against 100KW supplied by batteries). This factor is very important because it allows harnessing all the regenerative energy from braking system. In the case of batteries, this energy, specifically the intensity of charge is severely limited by its useful life, which is not the case with ultracapacitors.

- Substantial decrease of noise pollution both in electric mode and hybrid mode (with natural gas engine).

The new vehicle involves the development of a number of technologies:

Design and development of the new hybrid electric drive system for the vehicle and the body drive, both to the control software and hardware (components and their application in the re-used units)

- Development of specific control and power electronics. A new and exclusive software for the particular application will be developed based on experience, the study of technical specifications and the application requirements.

- Development of start-stop system to implement in the vehicle that will allow optimizing and reducing energy consumption recovering the most energy during braking.

- Development of new auxiliary equipment for power-operated brakes, power steering, alternator, and so on.

- Development of electronic control for the auxiliary electric engine for electric drive of hydraulic body services and container lift.

- The new hybrid electric vehicle combines a traditional internal combustion engine, powered by natural gas, with another electric traction engine. The objective is that, at low speeds the vehicle should move with electricity and when the inertia of the vehicle is reached, the conventional engine should start. Furthermore, in static situation, the thermal engine is intended to be stopped, being the energy to the body provided by the ultracapacitors system.

The technical improvements are even greater in urban environments, where the average speed of the route is low and includes a large number of starts and stops

© FCC Servicios Ciudadanos 2015 • Todos los derechos reservados • Prohibida la reproducción total o parcial en cualquier medio excepto con autorización expresa del propietario